Choose from our range of services.

In-Mould Labelling

With in-mould labelling (IML) Gard offers one of the most innovative printing methods for the optical finishing of cases.

Unlike traditional printing and labelling methods, with this film printing technology the labelling is done directly in the injection moulding process: Previously offset printed PP films are inserted automatically into the open injection mould and in sync with each mould “implanted” into the outer face of the housing half-shells.

The four-colour photo print is not only brilliant and scratch-resistant, but also forms a fixed component with the case. It is impervious to moisture and temperature influences, resistant to UV radiation and mechanical abrasion and allows the drawbacks of conventional adhesive labels to be forgotten: No peeling, no yellowing, no slipping, no reflective surfaces.

With the in-mould labelling of Gard cases a lasting and colour intensive colour print of the highest quality is assured. IML is therefore ideal for realising high-quality product branding.

Advantages of IML

The application of the IML technology has many advantages over other printing methods.

Optimal printing quality

Permanent image

Short production times and costs

Environmentally friendly

Advertising

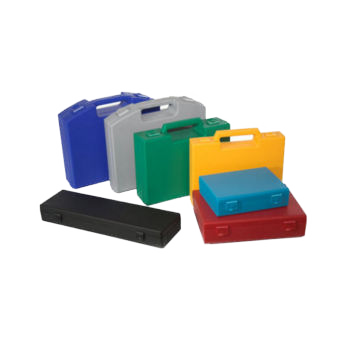

We offer the IML decoration technology for a selection of case models.

QUICK ENQUIRY

To get in touch, please use your preferred method below

Thank you for contacting us.

We will be in touch as soon as possible.